Pro Diamond Blades Collection – Concrete & Asphalt

Vortex Diamond’s Pro Diamond Blades Collection is designed for professional contractors and roadwork teams who demand maximum cutting speed, durability, and reliability. This collection includes two high-performance series:

- Pro Concrete Blade Series – engineered for reinforced and cured concrete, masonry, and construction materials.

- Pro Asphalt Blade Series – designed for asphalt, asphalt-over-concrete, and green concrete applications.

All blades feature laser-welded diamond segments, optimized bond formulas, and high diamond concentration for faster, cleaner cuts and longer blade life.

Pro Diamond Blades Comparison Table

| Feature / Application | Pro Concrete Blade Series | Pro Asphalt Blade Series |

|---|---|---|

| Primary Materials | Reinforced & cured concrete, masonry | Asphalt, asphalt-over-concrete, green concrete |

| Segment Height | 12mm – 13mm | 12mm |

| Bond Options | Soft / Medium / Hard | Multiple asphalt-optimized bonds |

| Undercut Protection | Optional | Slanted or radius undercut protection |

| Saw Types | Walk-behind (35–65HP), cut-off saws | Walk-behind, high-power road saws |

| Cutting Speed | Very fast on concrete | Extremely fast on asphalt |

| Best For | Roadwork, demolition, civil construction | Pavement, trenching, municipal work |

Featured Pro Blades

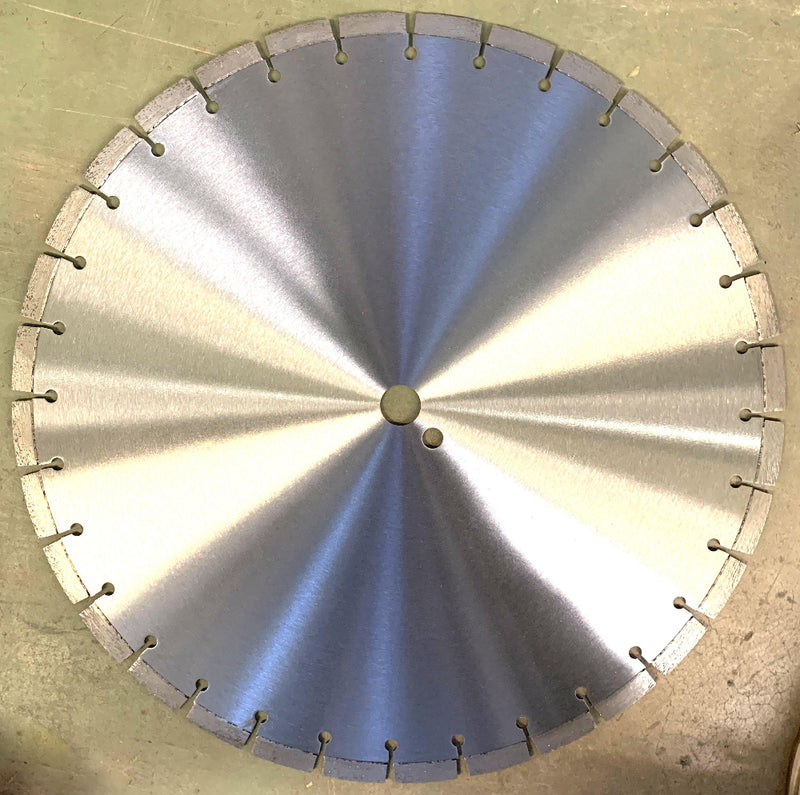

Supreme Pro Concrete Blades (13mm)

- For 35–65HP walk-behind saws

- Laser-welded 13mm diamond segments

- Bond options: P01–P05

- Ideal for reinforced concrete and high-demand cutting

Sizes: 14"–36" (custom available)

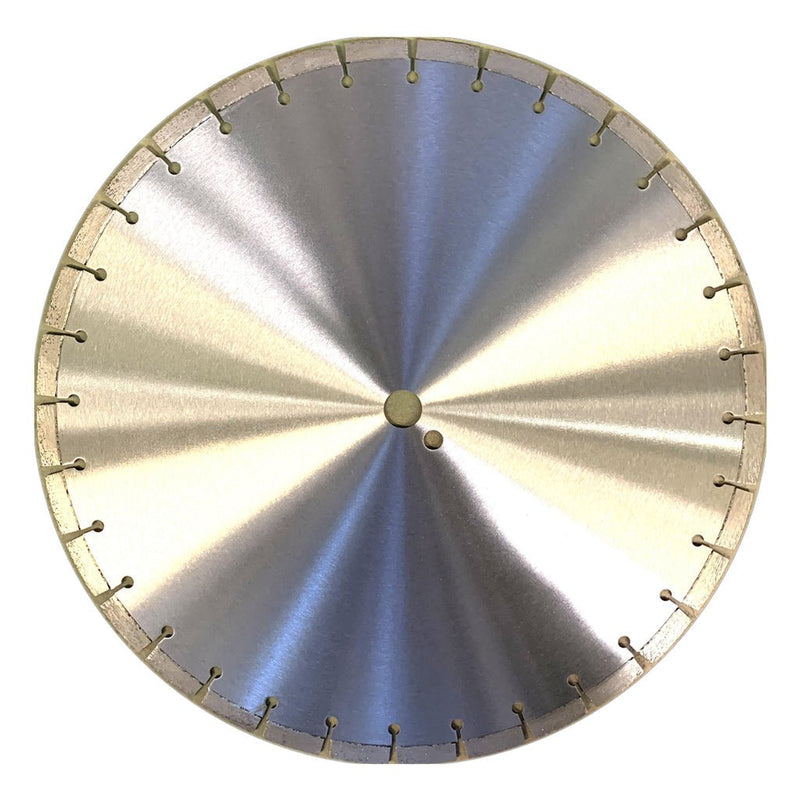

Premium Pro Concrete Blades (12mm)

- 12mm laser-welded segments

- Bond options for hard, medium, soft aggregates

- Compatible with walk-behind & handheld saws

Sizes: 14"–36"

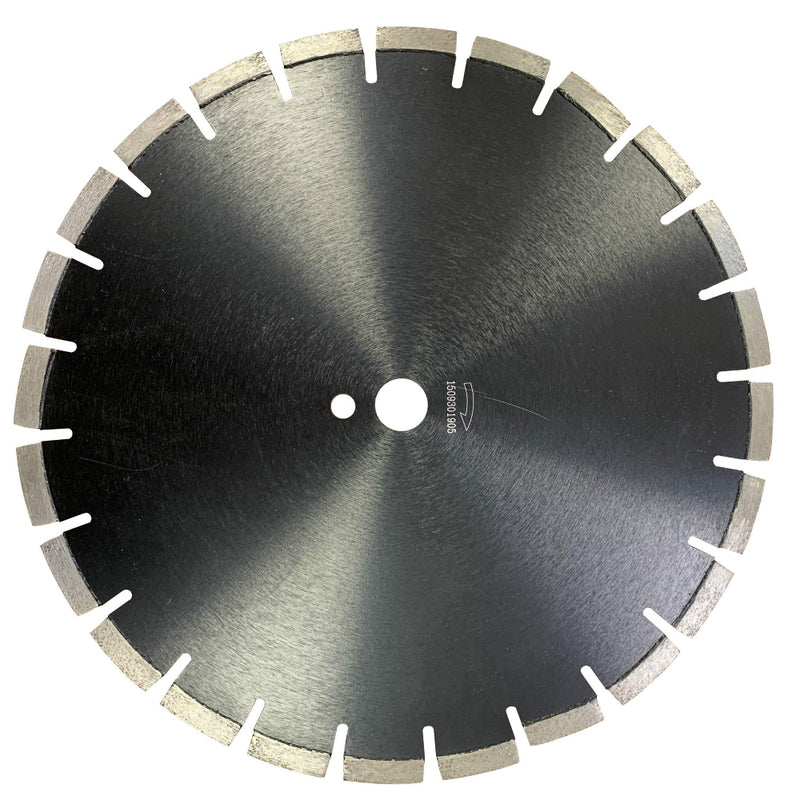

Supreme Pro Asphalt Blades (12mm + Slanted Protection)

- Slanted undercut-protecting segments

- Fast cutting on asphalt, asphalt-over-concrete, green concrete

- High diamond concentration and laser-welded construction

Sizes: 14"–36"

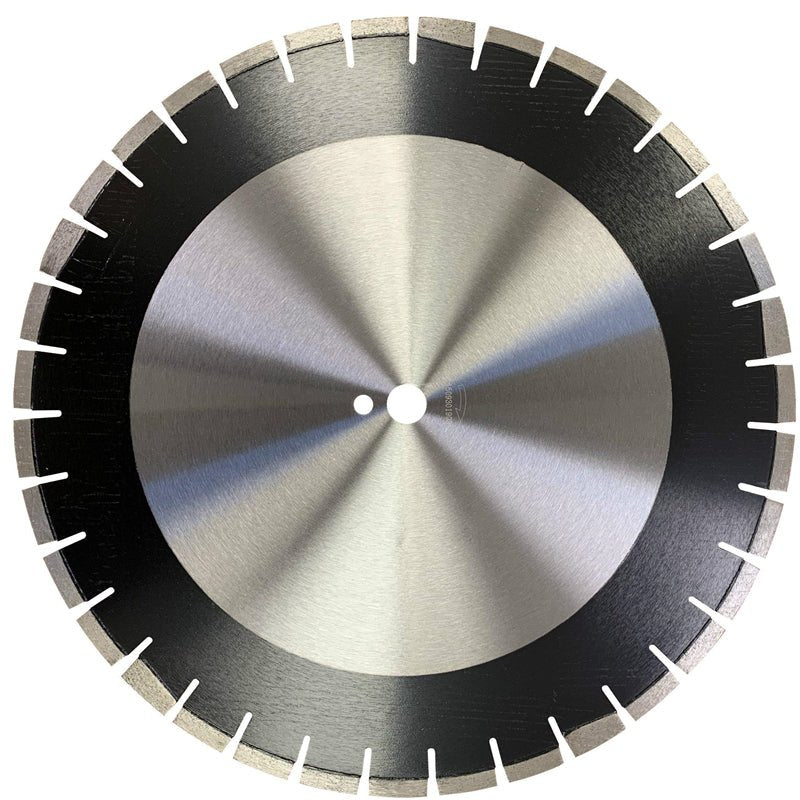

Premium Pro Asphalt Blades (12mm + Radius Protection)

- Radius-core protection for abrasive wear

- Multiple bond options for asphalt variations

- Designed for roadwork & municipal cutting

Sizes: 14"–26"

Frequently Asked Questions (FAQs)

What is the difference between Pro Concrete and Pro Asphalt blades?

Concrete blades use harder bonds to cut cured/reinforced concrete. Asphalt blades use softer, abrasive-resistant bonds with undercut protection.

Can one blade cut both asphalt and concrete?

Technically yes, but for best performance, use dedicated blades or a combo blade.

How do I choose the correct bond?

Hard material → soft bond. Soft material → hard bond. Pro Concrete blades P01–P05 follow this scheme.

What horsepower rating is required?

Optimized for walk-behind saws (35–65HP), cut-off saws, and road saws.

How long do Pro Diamond Blades last?

Depends on material, saw power, bond selection, and operator technique. Pro Series blades are engineered for longer life and lower cost per foot.

Do Pro Asphalt Blades include undercut protection?

Yes. Supreme Pro uses slanted segments; Premium Pro uses radius-core protection.

Can these blades be used wet or dry?

Yes, both wet and dry cutting are supported. Wet cutting increases blade life.