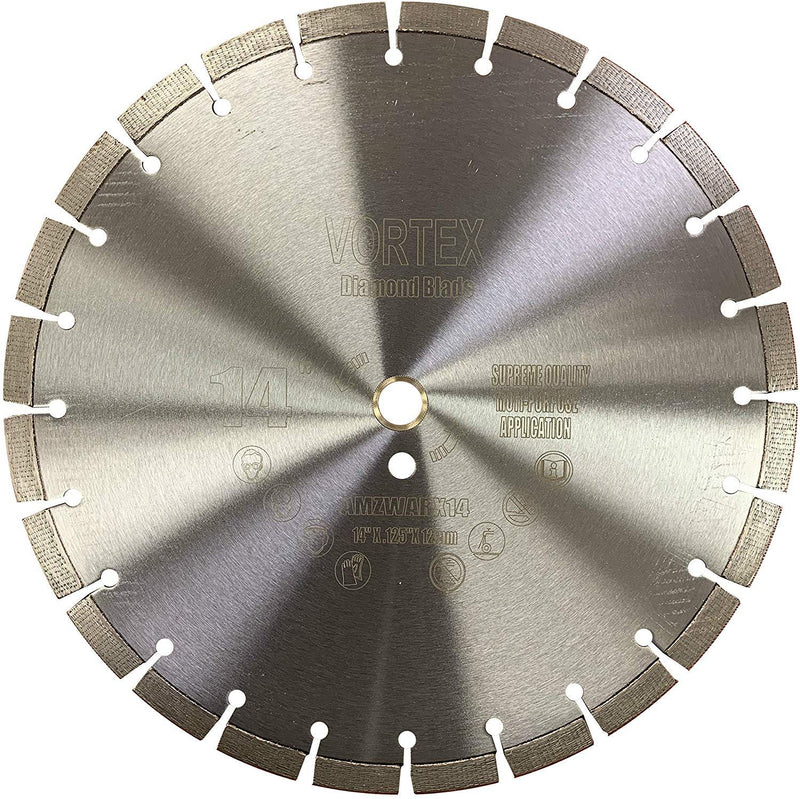

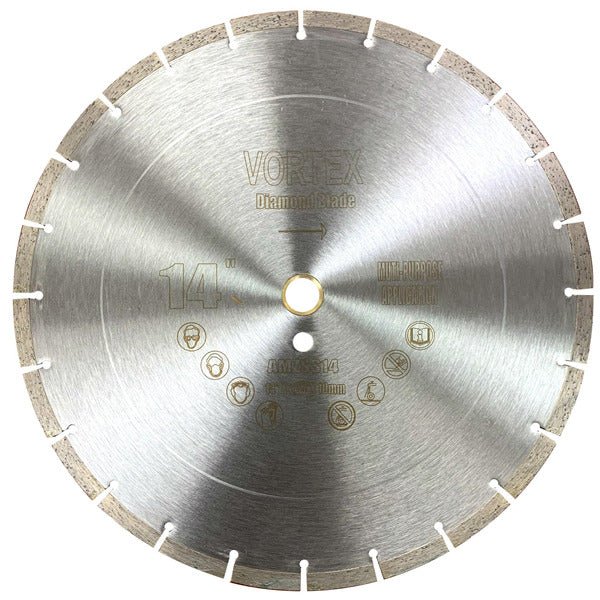

Vortex Diamond High-Speed General Purpose Blades — Durable Cutting for Concrete, Masonry & Asphalt

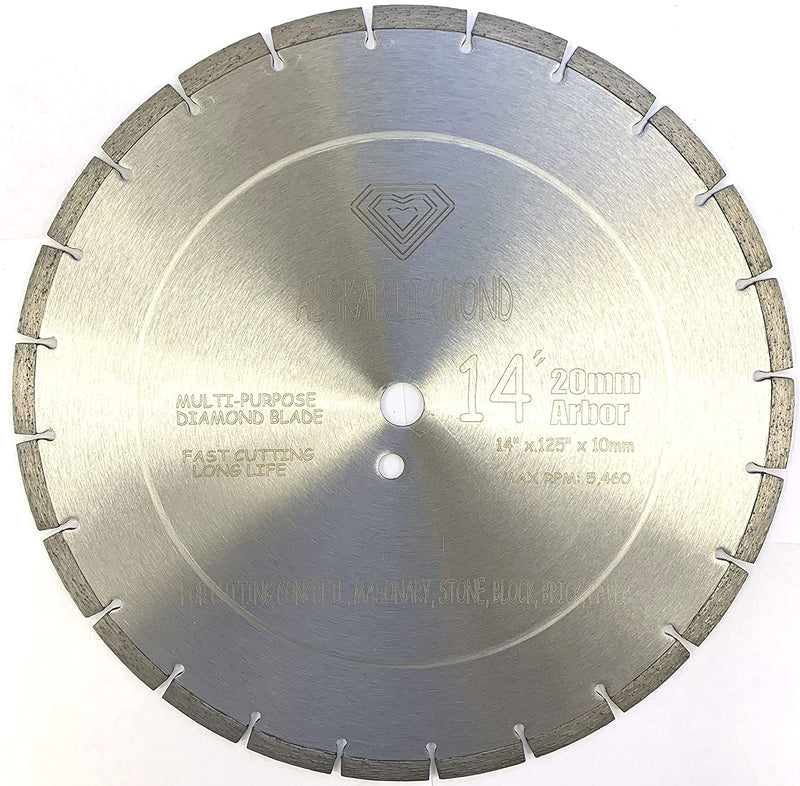

The Vortex Diamond High-Speed General Purpose Blades Collection is engineered for rapid, precise, and durable cutting across a wide range of materials, including concrete, masonry, brick, block, stone, and asphalt. Designed for high-speed hand-held saws, cut-off machines, and power saws, these professional blades deliver exceptional cutting speed, long life, and reliability, making them ideal for contractors, masons, and construction professionals.

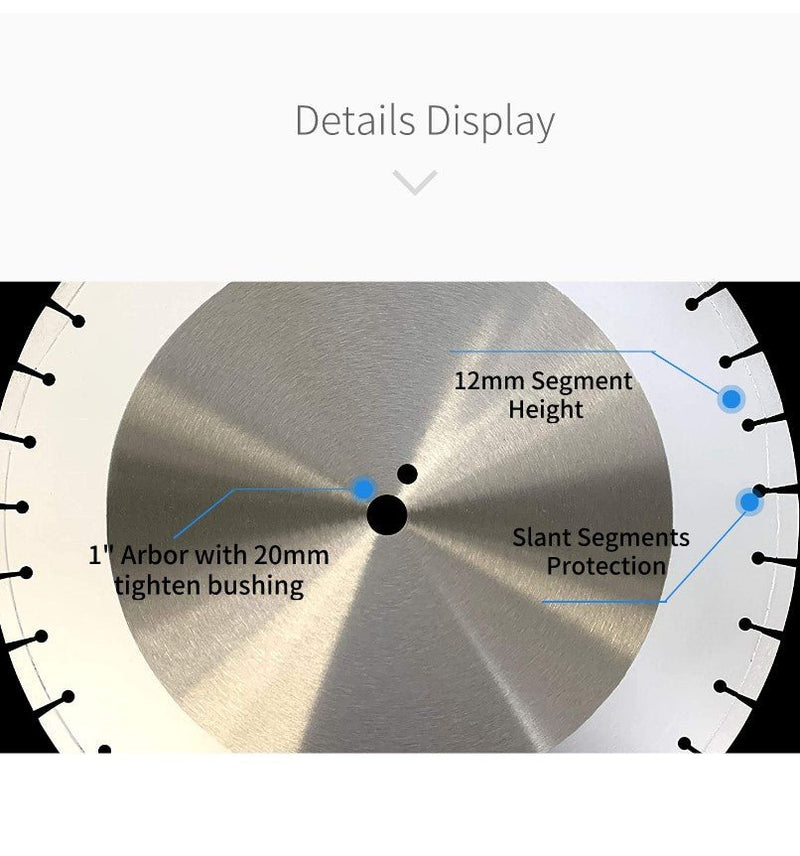

Each blade is manufactured with premium diamond segments and a reinforced steel core to ensure consistent performance and clean cuts, even under the toughest jobsite conditions.

🏷️ Five Quality Grades for Every Job

To meet the diverse needs of professionals, Vortex High-Speed Blades are available in five quality levels, allowing users to balance performance, durability, and economy:

-

Standard Sintered Grade – Cost-effective solution for light to medium-duty applications; reliable cutting at an economical price.

-

Premium Sintered Grade – Enhanced segment bonding for longer life and smoother cuts on general construction materials.

-

Standard Laser Welded Grade – Laser-welded segments for improved durability and precision, suitable for medium-duty professional use.

-

Premium Laser Welded Grade – Optimized for extended service life and higher cutting efficiency, ideal for demanding jobsite conditions.

-

Supreme Laser Welded Grade – Top-tier performance with fastest cuts, longest life, and maximum precision, perfect for heavy-duty, daily professional use.

⚙️ Key Features

-

Premium Diamond Segments – Fast, precise, and long-lasting cutting.

-

High-Speed Performance – Optimized for cut-off saws, hand-held saws, and power tools.

-

Multi-Material Cutting – Suitable for concrete, masonry, asphalt, brick, block, and stone.

-

Durable Construction – Sintered or laser-welded segments ensure consistent performance.

-

Cost-Effective Options – Choose the blade grade that fits your project needs and budget.

-

Professional Reliability – Trusted by contractors, masons, and construction teams worldwide.

🧭 Applications

-

Concrete demolition and jobsite cutting

-

Asphalt paving and road repair

-

Masonry wall openings and block trimming

-

Brick and stone cutting

-

Mixed-material construction projects

💡 Frequently Asked Questions (FAQ) — High-Speed Diamond Blades

1. What materials can high-speed diamond blades cut?

They cut concrete, masonry, brick, block, stone, and asphalt with speed and precision.

2. Can I use high-speed blades on cut-off saws?

Yes, designed for hand-held cut-off saws, high-speed power saws, and demolition saws.

3. What is the difference between high-speed and standard diamond blades?

High-speed blades have optimized segment geometry and steel cores for fast, clean cuts at higher RPMs.

4. Can these blades cut reinforced concrete?

Yes, premium diamond segments allow safe and efficient cutting of reinforced or cured concrete.

5. Do I need wet cutting for these blades?

Most are dry-cut capable, but some can be used wet to reduce dust and prolong segment life.

6. How do I choose the right quality grade?

-

Standard Sintered – Light/medium duty, economical

-

Premium Sintered – Smooth cuts, longer life

-

Standard Laser Welded – Medium-duty professional use

-

Premium Laser Welded – Heavy-duty, extended life

-

Supreme Laser Welded – Maximum performance for daily professional use

7. Can I cut asphalt with these blades?

Yes, Vortex High-Speed Blades are ideal for asphalt repair and paving applications.

8. Are these blades suitable for mixed-material projects?

Yes, engineered for versatility, cutting both masonry and asphalt efficiently.

9. How do I maximize blade life?

-

Use the correct blade for the material

-

Avoid forcing cuts or overheating

-

Allow cooling intervals

-

Clean debris regularly

10. What safety precautions should I follow?

Wear goggles, gloves, and ear protection. Ensure proper saw compatibility, secure material, and follow recommended RPM and feed rates.