Brocas de diamante Vortex para fresado de carreteras: herramientas de alto rendimiento para fresado de asfalto y hormigón

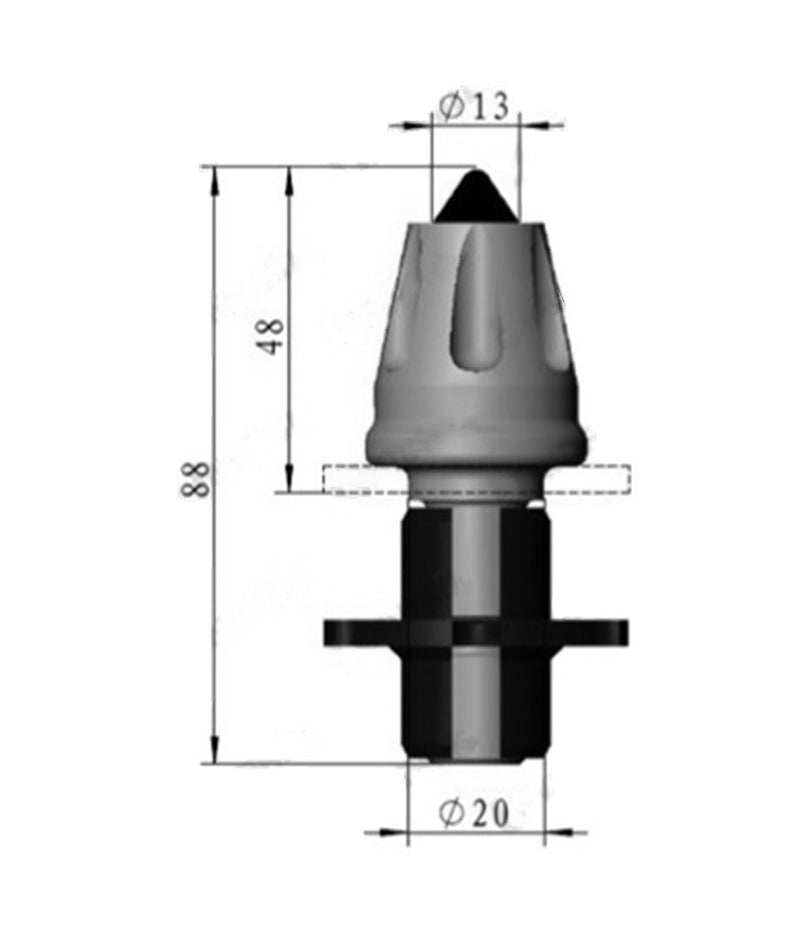

La colección de brocas de diamante para fresado de carreteras Vortex incluye brocas de calidad profesional para asfalto y hormigón , también conocidas como picas de cepillado, dientes de fresadora o brocas para fresadora de carreteras . Estas piezas de desgaste esenciales están diseñadas para la construcción de carreteras y la remoción de superficies , ofreciendo un rendimiento rápido, preciso y duradero en cada trabajo.

Instaladas en el tambor de fresado de las fresadoras de carreteras , estas brocas cortan, quitan y preparan eficientemente las superficies de las carreteras , lo que ayuda a los contratistas y equipos de obras viales a completar proyectos con la máxima eficiencia y un tiempo de inactividad mínimo .

⚙️ Tipos disponibles

-

Brocas para fresado de asfalto : diseñadas para superficies de carreteras más blandas , proporcionan una velocidad de corte rápida, excelente resistencia al desgaste y una eliminación suave del asfalto .

-

Brocas para fresado de hormigón : diseñadas para agregados más duros , ofrecen una resistencia al impacto superior, mayor durabilidad y un rendimiento duradero durante operaciones de fresado de hormigón de alta resistencia.

Cada tipo está optimizado para modelos específicos de fresadoras y condiciones de la superficie de la carretera , lo que garantiza la máxima productividad, una vida útil más prolongada y costos de mantenimiento reducidos .

🧭 Aplicaciones

-

Fresado de asfalto y remoción de pavimento

-

Cepillado y preparación de superficies de hormigón

-

Proyectos de construcción y reparación de carreteras

-

Mantenimiento de infraestructuras viales y municipales

-

Operaciones de fresado de áridos blandos y duros

Preguntas frecuentes (FAQ) — Brocas para fresado de carreteras

1. ¿Para qué se utilizan las brocas para fresar carreteras?

Las brocas para fresado de carreteras se instalan en tambores de fresado para cortar, remover y cepillar superficies de asfalto u hormigón durante proyectos de construcción o reparación de carreteras.

2. ¿Cuál es la diferencia entre las brocas para fresar asfalto y hormigón?

-

Brocas para asfalto : Diseñadas para superficies más blandas , proporcionando cortes rápidos y alta resistencia al desgaste .

-

Brocas para hormigón : diseñadas para agregados más duros , ofrecen durabilidad, resistencia al impacto y una larga vida útil .

3. ¿Puedo utilizar estas brocas en cualquier fresadora de carreteras?

Las brocas de fresado Vortex son compatibles con la mayoría de las fresadoras de carreteras estándar , pero es esencial seleccionar el tipo y tamaño de broca correctos para su tambor y aplicación.

4. ¿Cuánto duran las brocas para fresar carreteras?

La longevidad depende de la dureza de la superficie, la velocidad de fresado y las condiciones de operación , pero las brocas de diamante Vortex están diseñadas para lograr la máxima durabilidad y reducir el tiempo de inactividad .

5. ¿Son fáciles de instalar las brocas de repuesto?

Sí. Las brocas están diseñadas para un reemplazo rápido en los tambores de fresado , lo que minimiza las demoras en el lugar de trabajo.

6. ¿Puedo utilizar brocas para fresar asfalto sobre hormigón?

No se recomienda. Utilice brocas para asfalto para superficies blandas y brocas para concreto para agregados duros para garantizar un rendimiento adecuado y una larga vida útil.

7. ¿Cómo elijo la broca de fresado adecuada?

Considere el tipo de superficie de la carretera, el modelo de la fresadora y los requisitos del proyecto . Vortex ofrece orientación para la selección óptima de la broca.